Your cart is currently empty!

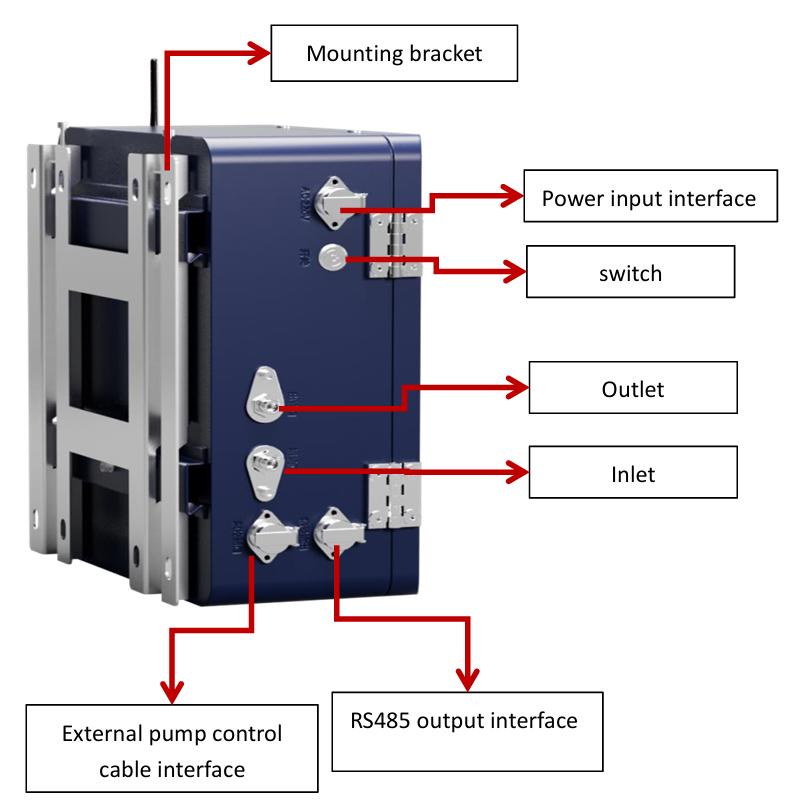

Online Oil Condition Monitoring – OOCM01

Oil online monitoring technology is the online monitoring device directly installed on the system pipeline or oil tank. It can detect at any time during the system working process , omit the cumbersome operating procedures, and avoid additional external pollution, so the detection speed is fast, the cost is low, the measurement results can better represent the real physical and chemical properties of the system oil and pollution status.

Description

Oil online monitoring technology is the online monitoring device directly installed

on the system pipeline or oil tank. It can detect at any time during the system working

process , omit the cumbersome operating procedures, and avoid additional external

pollution, so the detection speed is fast, the cost is low, the measurement results can

better represent the real physical and chemical properties of the system oil and

pollution status.

Main parameters and significance of oil online intelligent monitoring:

- Oil Kinematic Viscosity: Utilizes fluid vibration sensing technology for real-time monitoring of various oil kinematic viscosity changes.

- Change Hazards: Excessive viscosity can deteriorate oil fluidity, leading to increased heat generation, while excessively low viscosity can compromise the oil film, causing wear and tear on friction pairs.

- Monitoring and Prevention: Detects oil mixed with water, misfuelling, deterioration due to aging, Identifies water pollution from tank breathing, pipeline seal failure, or cooler leakage

- Trace Moisture or Moisture: Uses polymer film capacitance or electrochemical impedance spectroscopy (EIS) sensing technology to monitor oil moisture changes in real-time.

- Moisture Damage: Causes emulsification and oxidation of oil, affecting oil film establishment, and leads to system rust.

- Oil Contamination: Employs optical particle counting technology to monitor the concentration (number, size, and grade) of contaminated particles in the oil in real-time.

- Contamination Hazards: Can cause valve blockage, scratches and wear on valve cores, pumps, journals, bearing shells, gear bearing surfaces, and oil pressure fluctuations, leading to lubrication issues.

System functions :

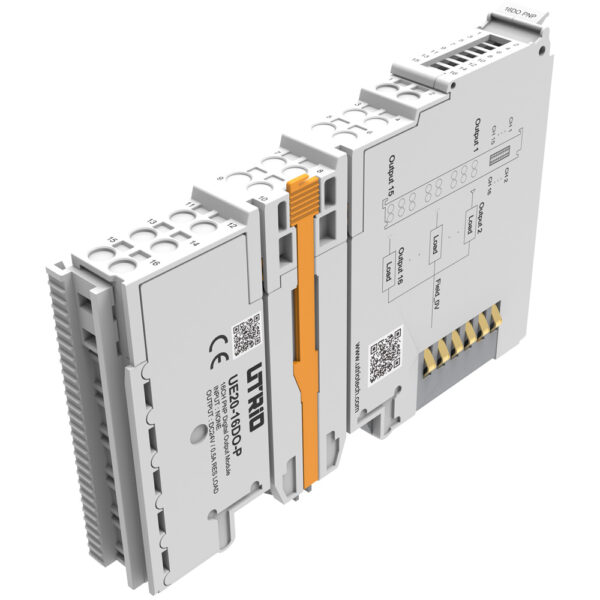

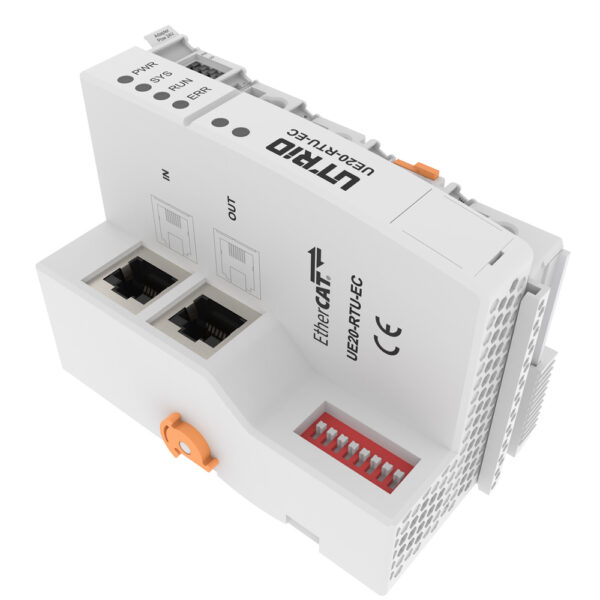

- Integrated design collection, control, monitoring and transmission adopt integrated design, the system is stable and reliable.

- Communication mode: CAN bus, RS485, 4G\5G integrated.

- Information processing mode: multi-information processing, which can realize joint analysis of multi-data indicators, prediction calculation, real-time alarm, and intelligent early warning of system monitoring data.

- Kinematic viscosity correction: real-time correction calculation of viscosity-temperature equation; Real-time kinematic viscosity regression standard temperature kinematic viscosity calculation.

- Monitoring indicators: real-time data monitoring of lubricating oil viscosity, moisture, pollution, oil temperature and other indicators of monitoring equipment.

- Data processing and display: support real-time observation indicators.

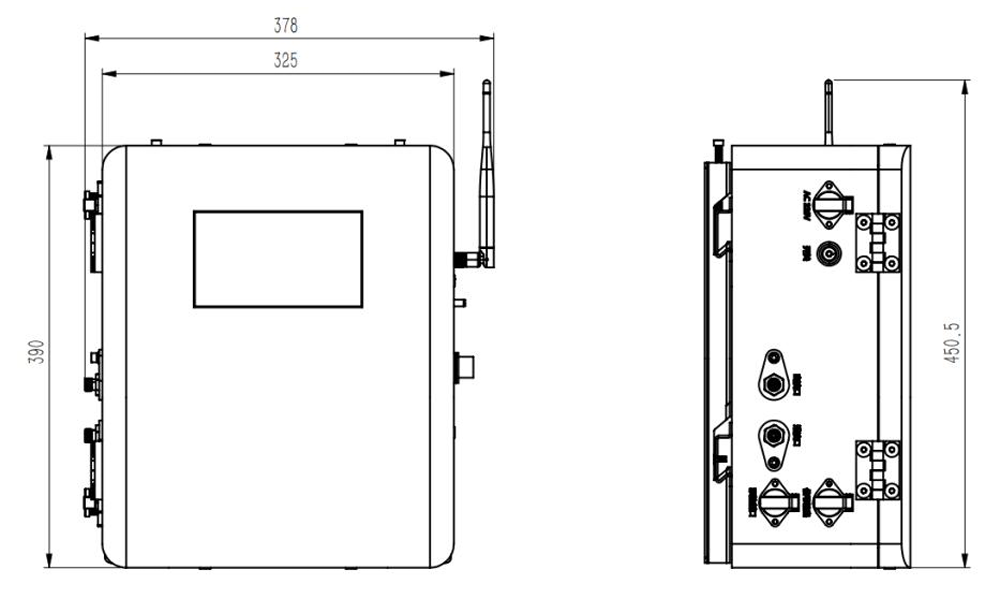

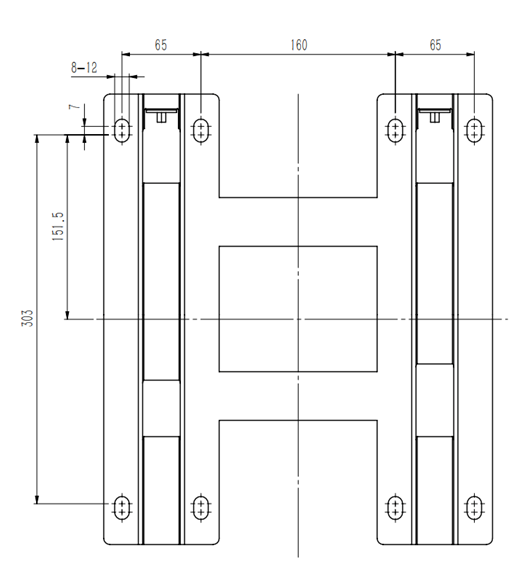

Bracket Dimension

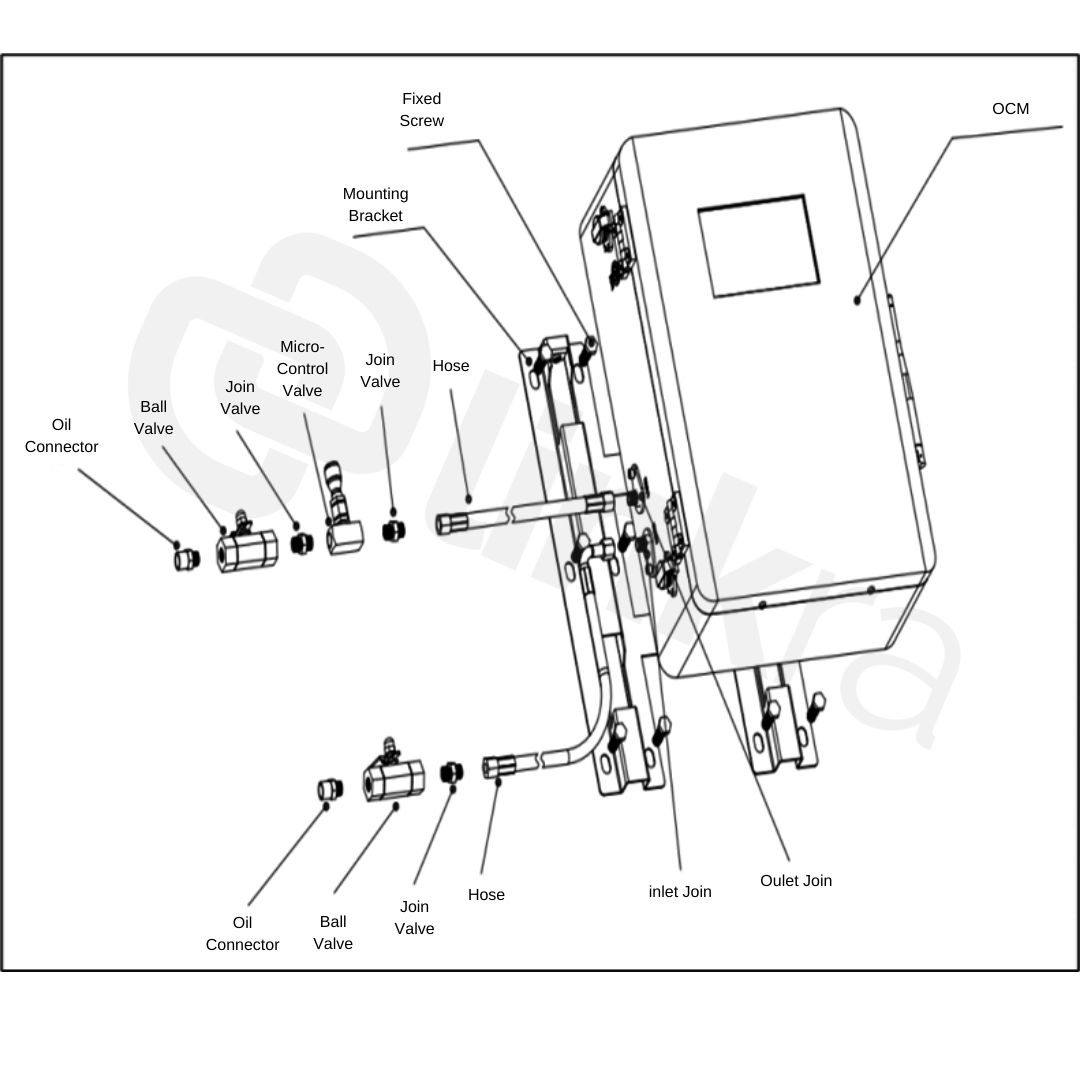

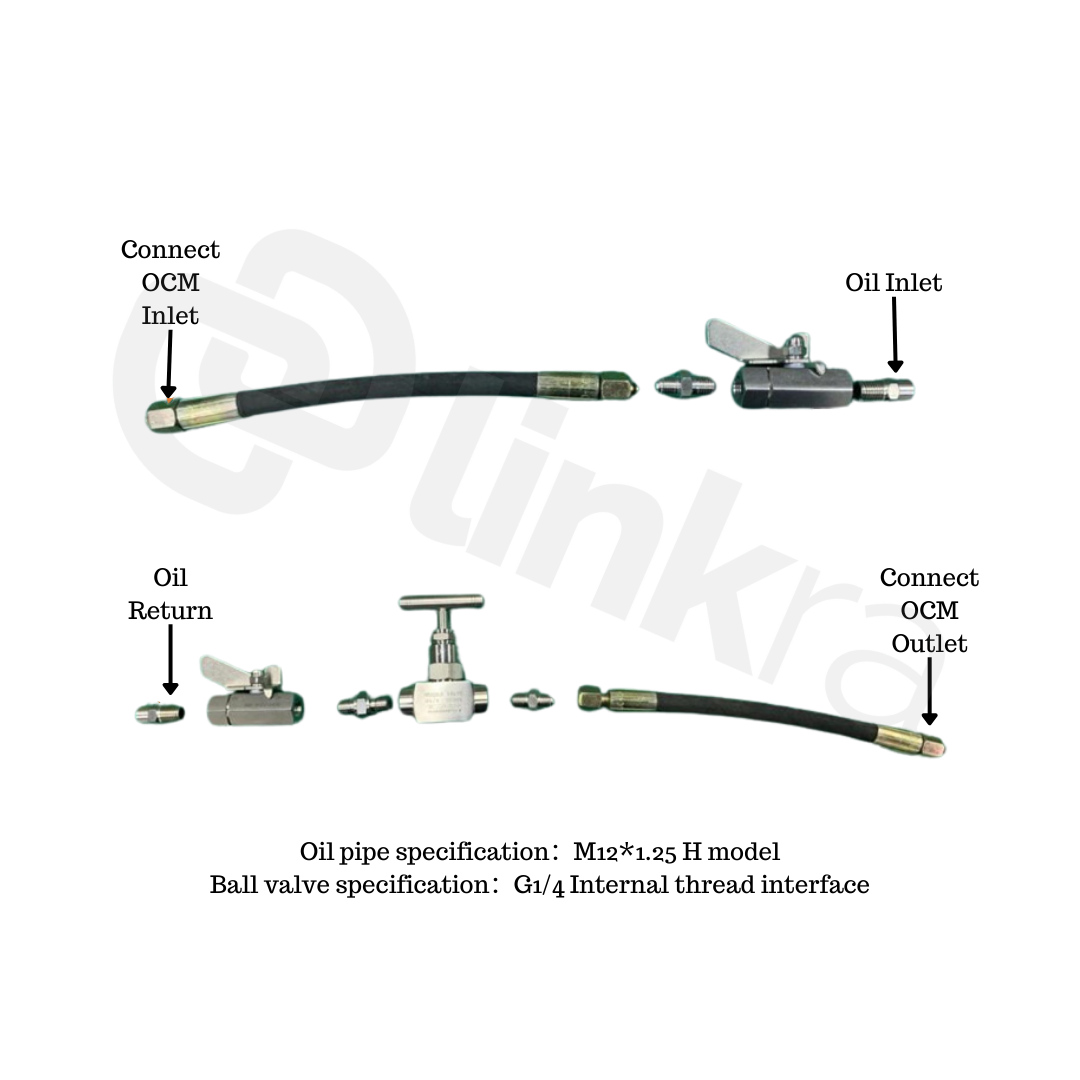

Equipment Instalation

Reviews

There are no reviews yet.